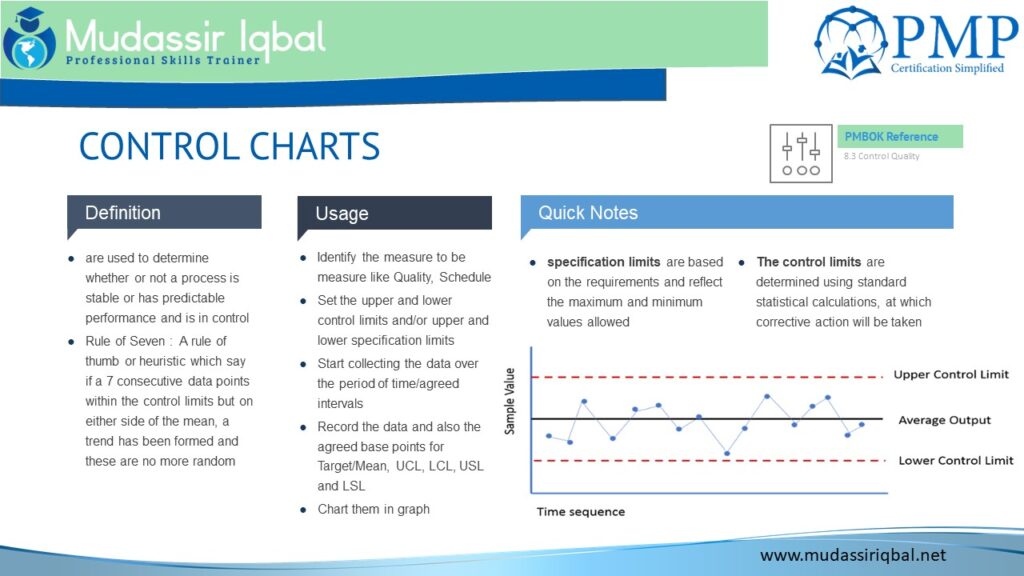

A control chart is a tool used to determine a process’s predictability, behaviour, and stability over time.

It is ideal for repetitive processes with predictable results.

- The centerline is the mean or average.]

- The specification limits also known as tolerance limits, are the predetermined acceptable range (the maximum and minimum values allowed) for a particular process or product characteristic.

-

- Upper Specification Limit (USL): It is the maximum allowable value for the process characteristic. If the value exceeds the USL, it indicates that the product or process is outside the acceptable range.

- Lower Specification Limit (LSL): It is the minimum allowable value for the process characteristic. If the value falls below the LSL, it indicates that the product or process is outside the acceptable range.

- The control limits are statistical thresholds used to assess the stability and performance of a process over time. They are derived from the data collected from the process and are based on the inherent variability in the process

- Upper Control Limit (UCL): It is a calculated value that defines the upper boundary or threshold for the process data points. Any data point that exceeds the UCL suggests a potential out-of-control condition.

- Lower Control Limit (LCL): Similar to the UCL, the LCL is a calculated value that defines the lower boundary or threshold for the process data points. Any data point that falls below the LCL also suggests a potential out-of-control condition.

It is a graphic display of a process over time. Control charts measure the performance of a process to ensure it is in control. When a process is in control the results of the process are consistent with expectations. When it is not in control there are outliers or unexpected results. Every piece of data which is measured will show some degree of variation: no matter how much we try, we could never attain identical results for two different situations – each result will be different, even if the difference is slight.

It is used for

- Used to monitor various types of output variables

- Used to monitor cost and schedule variances, volume, frequency of scope changes, or other management results to help determine if the project management processes are in control

- Determine whether a process is stable.

- Find problems as they occur in an ongoing process.

- Assess the effectiveness of a process change.

- Predict the range of outcomes for a process.

- Assess patterns of special cause variation to identify non-routine events.

- Determine whether improvements should target non-routine events or the underlying process itself.

Rule of 7

The “rule of 7” is a commonly used rule of thumb in statistical process control, specifically for detecting potential process shifts or non-random variation in a control chart. It states that if 7 consecutive data points fall on the same side of the control chart’s mean line (either all above or all below), it suggests the presence of a special cause or assignable variation in the process.

It is important to note that the “rule of 7” is a guideline and not a strict statistical rule. Its purpose is to draw attention to potential process shifts, but statistical analysis and additional tests may be required to confirm the presence of a significant change in the process.

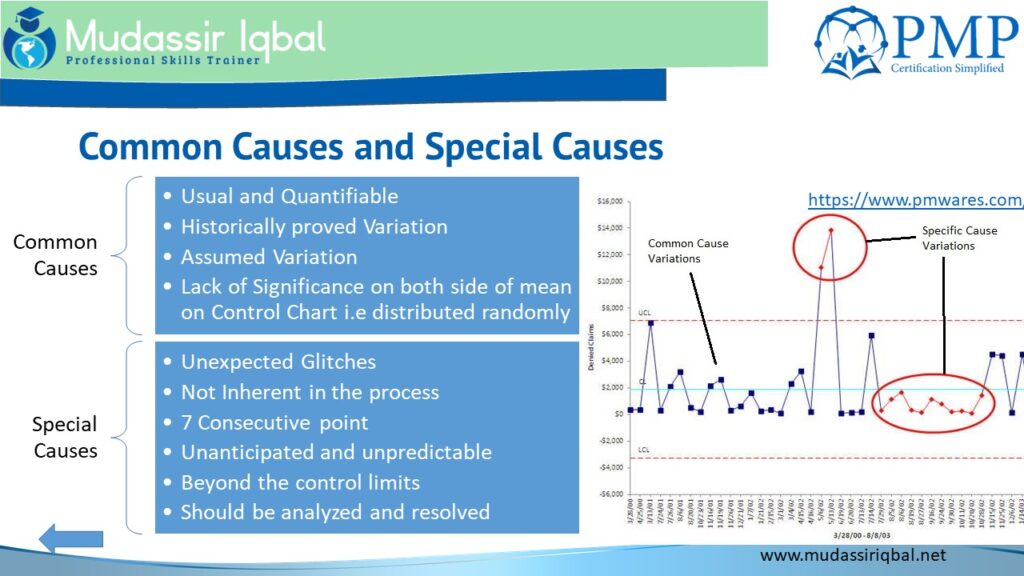

Common Causes

Common causes, also known as random or natural causes, are the inherent sources of variation that are present in any process. They represent the normal, expected variation that occurs due to a combination of numerous factors, including equipment, materials, operators, and environmental conditions. Common causes of variation are typically stable and predictable over time.

Examples of common causes include minor fluctuations in temperature, natural variations in raw materials, normal wear and tear on equipment, or slight differences in operator performance. These variations are typically accounted for within the normal range of process performance and are considered inherent to the process itself.

Special Causes

Special causes also referred to as assignable causes or non-random causes, are sources of variation that are not part of the normal process variation. They are typically sporadic or infrequent events that cause significant deviations from the typical process performance.

Examples of special causes include equipment malfunctions, operator errors, power outages, sudden changes in raw material quality, or other unexpected events that lead to significant variations in the process

Further Reading

Control Chart: Uses, Examples, and Types – Statistics By Jim